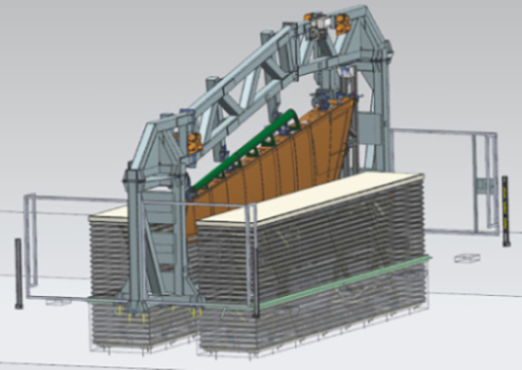

Assembly applliances

Modular assembly lines mainly use assembly jigs and appliances which, to a large extent, govern the quality of geometry of the assemblies and units of an aircraft. The useful life of such assembly appliances should be long enough to support production for several decades. Besides, they should be easily repairable and allow modifications to meet production needs.

All assembly appliances of our company are designed using a laser tracker based assembly technique while the appliance components are manufactured by CNC machines.

Our company pursues a policy of packaged delivery of a product meaning that all requisite utility lines, including a pneumatic system, electrical connections, lighting, suction systems, etc., are integrated in the jig structure as early as the design stage. For complex operations, we where possible use mechanical aids built in the jigs. To this end, the cutting-edge hardware components similar to those used in machine building are employed.

Each assembly appliance is always an individual project. Launching the assembly lines into production requires a lot of work of designers, with manufacturing carried out on a one-off basis imposing certain limitations. Our company possesses sufficient production facilities to implement large-scale projects on preparation of aircraft assembly processes and is experienced in supporting such projects during assembly of the first products.

AVIATION

CONSULTING -

TECHNO CJSC

The energy of joint solutions

129164, Russia, Moscow, st. Yaroslavskaya, 8, building 5, office 318

Tel.: +7 (495) 626-5471

Fax: +7 (495) 626-5472

E-mail: aviacons@aviacons.ru