CNC positioners

Any assembly process involves positioning. Positioning may be carried out with reference to marks, mating holes, appliance locks, etc. The most up-to-date positioning method uses special CNC devices. This method has a number of advantages, including, without limitation, automatic operation and lack of a human factor (owing mainly to use of robotic devices), positioning of large-size and nonrigid constructions.

CNC positioners are applicable in various combinations for high-precision manipulations with large and heavy products, positioning of parts for machining, unit assembly. All assembly jigs of our company use various modifications of such positioners to ensure maximum assembly accuracy.

High accuracy characteristics are provided owing to a combination of the advanced highly rigid structure, precision servomechanisms and sensitive motion/load transducers.

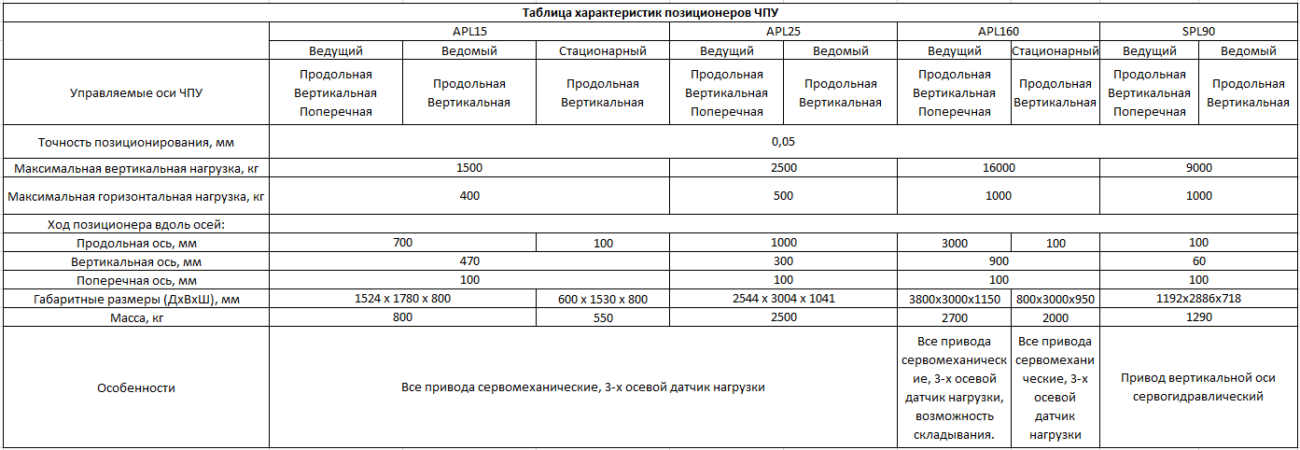

Our company has developed and put into production a wide range of CNC positioners with a maximum load bearing capacity ranging from 1.5 to 16 tons. Thus, the positioner may be chosen from the available range or designed to suit a particular task.

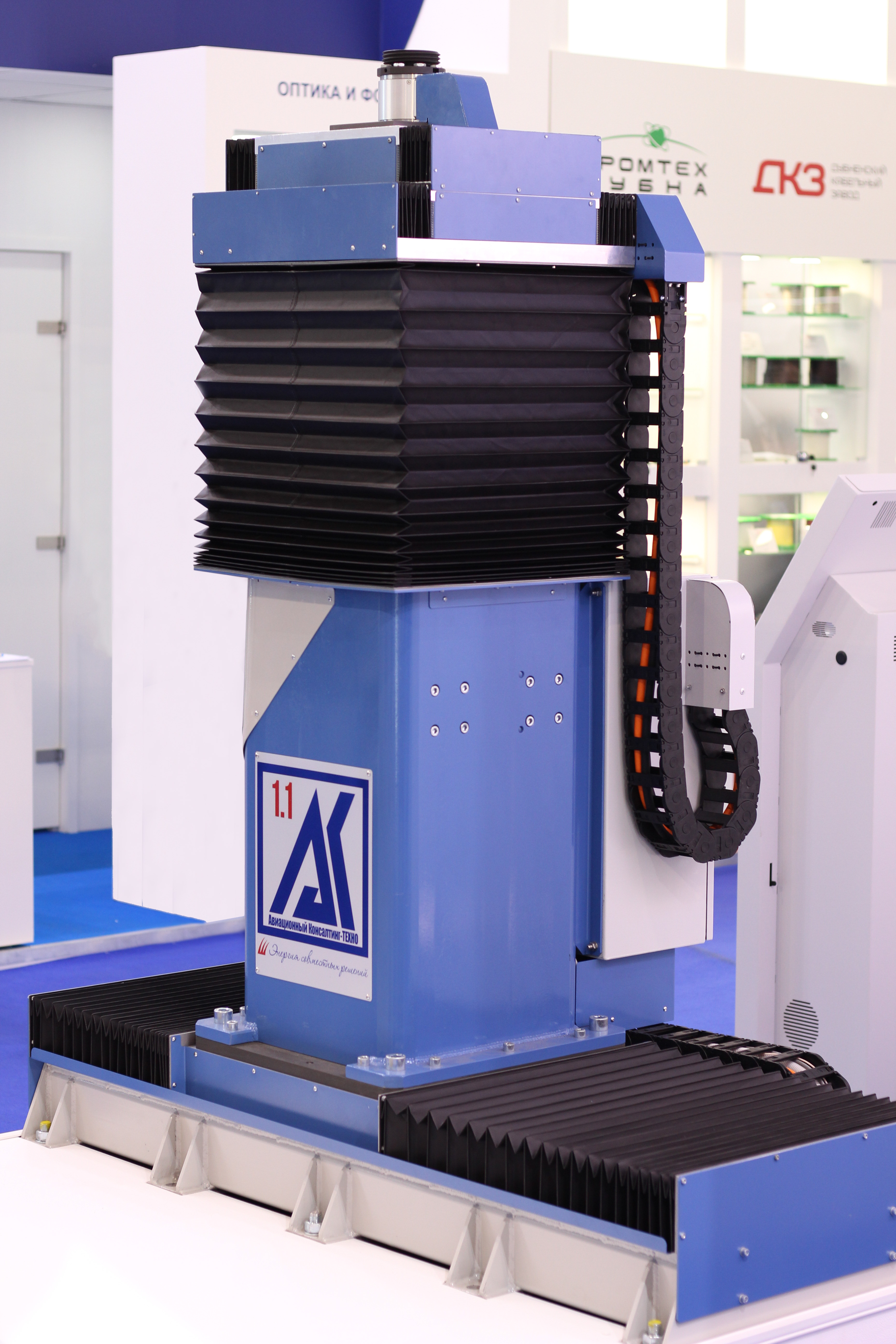

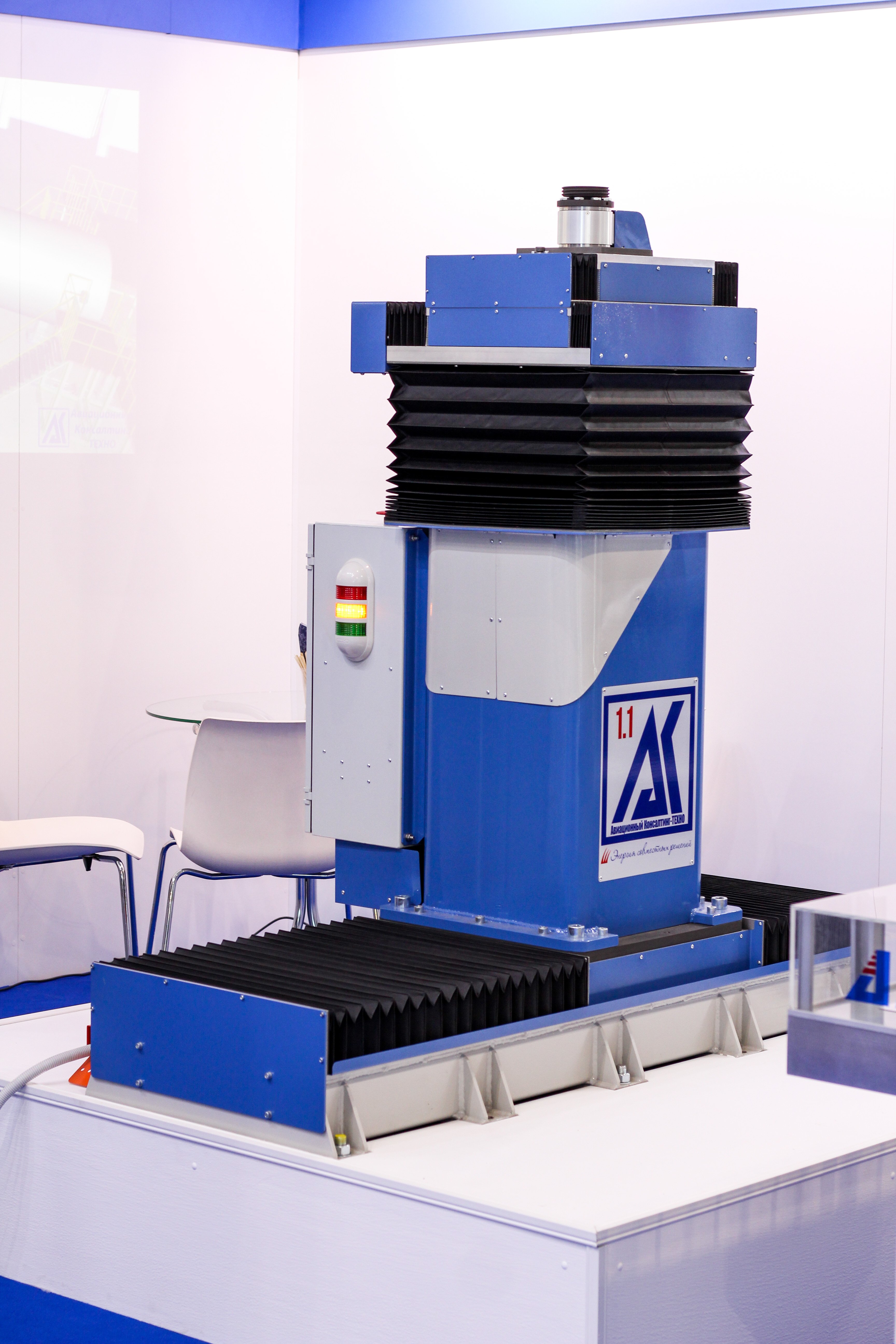

APL15

APL15

APL25 + SPL90

Synchronous operation of eight APL15 positioners

The CNC positioners are equipped with 3-axis load transducers for appropriate measurement ranges, servo drives, servohydraulic drives, ballscrews and planetary reduction gears made by leading manufacturers.

AVIATION

CONSULTING -

TECHNO CJSC

The energy of joint solutions

129164, Russia, Moscow, st. Yaroslavskaya, 8, building 5, office 318

Tel.: +7 (495) 626-5471

Fax: +7 (495) 626-5472

E-mail: aviacons@aviacons.ru